A new calibration standard for solid-state lighting

Challenge

Around 12% of electricity consumption in the world is used for lighting. More efficient systems have the potential of allowing Europe to save up to 34 TWh of electricity by 2030, reducing CO2 emissions by 7 million tonnes per year. Incandescent lights – where electricity flowing through a thin metal filament, such as tungsten, heats it until it glows – have been in use since the 19th century. In these only around 10% of the energy used is emitted as visible light and the majority is lost as heat. During operation, the filament that creates the light also gradually evaporates, limiting the bulb’s lifetime.

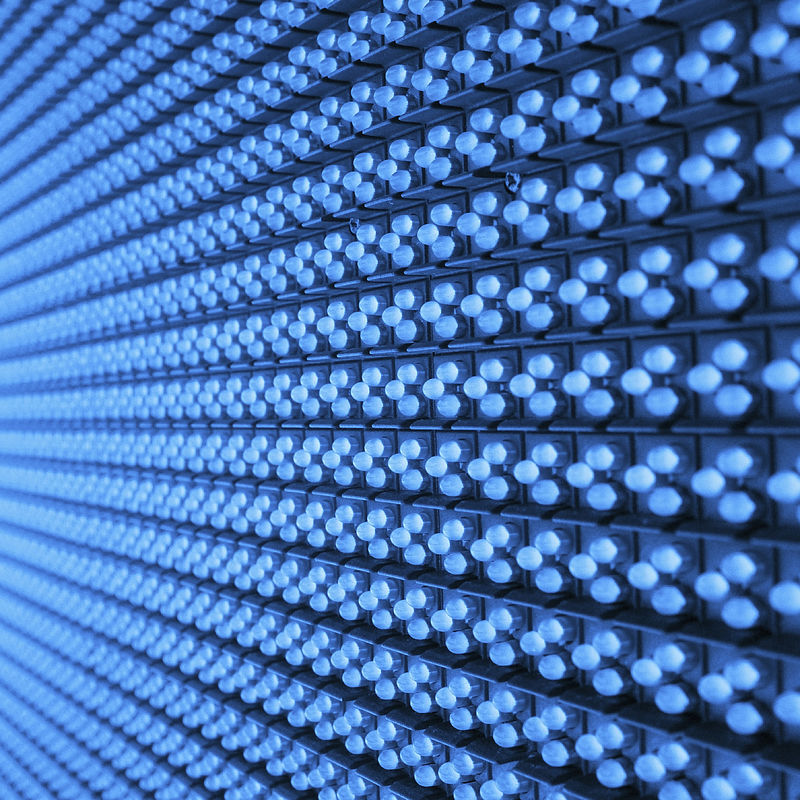

The Ecodesign of Energy-Related Products Directive (2009/125/EC) implemented a gradual phase out of filament-based lighting in Europe from 2009 to 2012, to be replaced by solid-state lighting (SSL) products. This includes LEDs, which use 75-90% less power and last up to 50x longer than filament bulbs.

An accurate rating of the energy consumption – and the light output – of SSL products is important to both support the specification claims of the manufacturer and help ensure customer confidence in this form of technology.

Photometers determine lighting characteristics by measuring illuminance, but are typically calibrated against filament-based standards, such as CIE standard illuminant A. As LEDs have a different spectral output than filament standards, photometers often generate higher measurement uncertainties when assessing SSL products. Previously, no metrological standards suitable for calibrating these instruments for SSL products were available in Europe.

Solution

The PhotoLED project assessed the spectral mismatch errors in photometer calibration for measurement of 1516 different LED sources by comparing the use of CIE standard illuminant A and a newly developed 4103 K LED reference spectrum. Based on this reference, suitable white LEDs with correlated colour temperature close to 4103 K were selected for incorporation into 6 prototype luminous intensity standard (LIS-A) lamps for calibration of photometers used for measuring SSL. The results showed that, when photometers are calibrated with a white LED source, the spectral mismatch when measuring white LEDs is reduced by a factor of two, on average.

The new prototypes, with internal heat sinks and fans to ensure thermal stability, were characterised for their mechanical, electrical and optical specifications, and the stability of the LEDs measured using a photometric bench. Two of the LIS-A prototypes were then calibrated with three different detector types at partner laboratories before undergoing a pilot interlaboratory comparison. Since the prototypes contained no sensitive filaments or glass bulbs, they demonstrated greater robustness to transportation shocks than traditional incandescent calibration standards.

Impact

In 2021, members of the consortium founded a new company, Luminous Intensity, to commercialise the LIS-A standard. The new LED standard LIS-A is designed to provide a technically more advanced alternative to incandescent standard sources used by calibration laboratories. It is anticipated that in the future, laboratories will increasingly move towards using LED standards in photometer calibrations.

With a closer spectral match to LEDs and other SSL products, the company’s standard also degrades 10-100x less during operation than traditional tungsten calibration lamps, and temperature and misalignments have only negligible influence on the measurements. It is also more robust during transportation than the older standards, which often had to be transported between laboratories by hand.

Furthermore, as the light emitted by the LEDs is more directional towards the detector, and the standard does not contain glass bulbs, there is no light affecting results from internal reflections, resulting in low measurement uncertainties.

For manufacturers of lighting products and all products involving components that emit light, such as car headlights, the use of LED calibration standards, like Luminous Intensity’s LIS-A in calibration of instruments, will enable more reliable measurements during product development and testing, including energy classification of SSL. This leads to improved quality and safety of products, while helping reduce costs and accelerate development of this technology. For consumers, the increased confidence in the stated performance of products will enable better informed choices.

Importantly, in the long run this will help reduce annual energy consumption from lighting, with a commensurate reduction in CO2.

- Category

- EMPIR,

- EMN Advanced Manufacturing,