Advanced detail sensitivity monitoring by new concepts to improve the reliability of safety relevant products using industrial computed tomography

Short Name: SensMonCT II, Project Number: 23NRM05

Supporting the digital transformation in Europe by improving detail sensitivity of iCT measurements

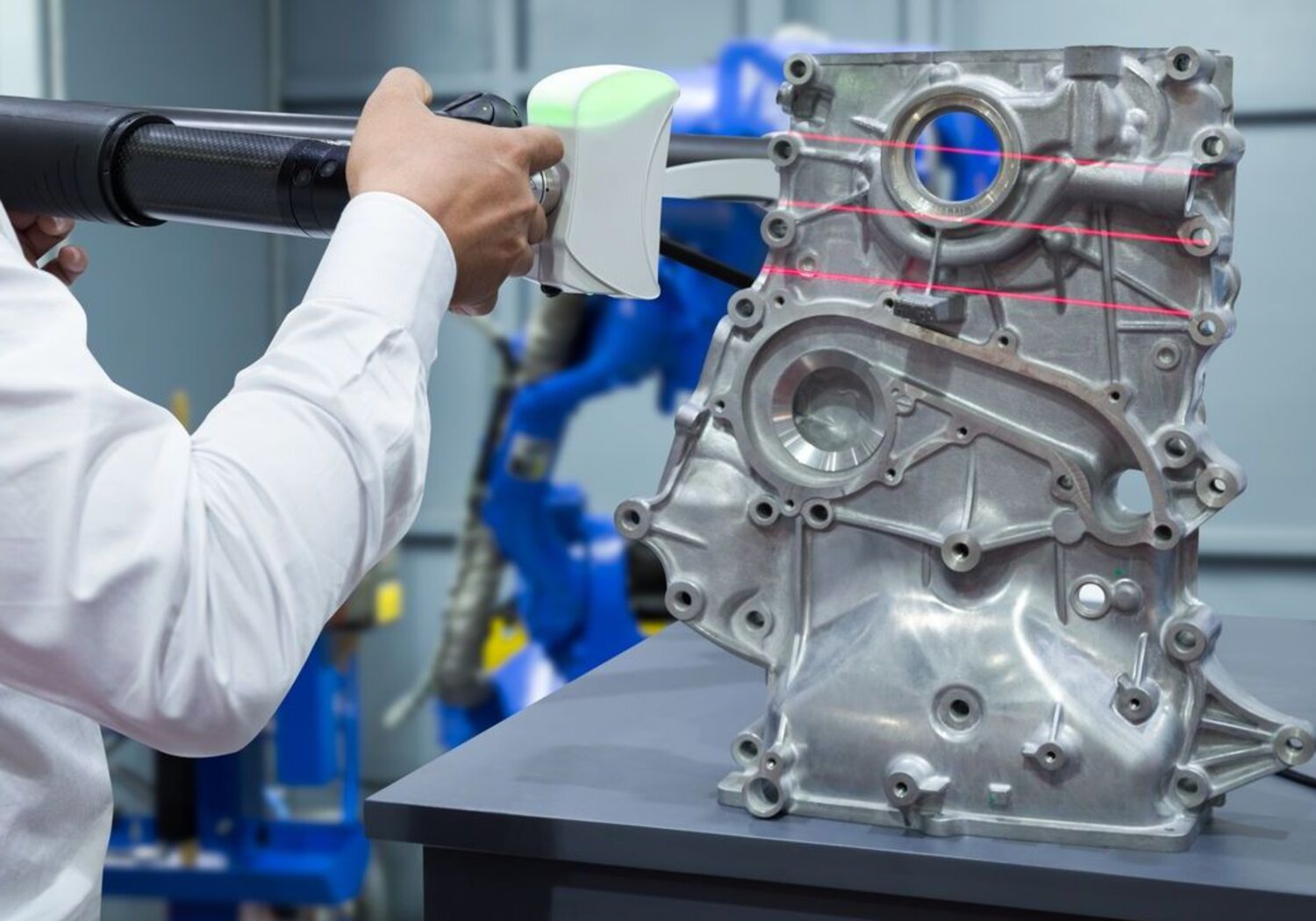

Digital applications including Industry 4.0 often use industrial computed tomography (iCT) data for their functions. However, at the moment, detail sensitivity of iCT systems is evaluated by human operators, and therefore unreliable and expensive. There is a metrological need to develop traceable measurement and monitoring methods to assess detail sensitivity of iCT for the minimum detectable defect or flaw sizes without relying on human observers. This is an essential step to support the EU’s aims for the digital transformation in Europe and the United Nation’s sustainability goal for industry, innovation and infrastructure. However, new measurement methods, reference software, and standards need to be developed to fill this meteorological gap.

The project aims to develop new test gauges that will help determine iCT detail sensitivity. Additionally, a new automated evaluation algorithm will be published that can determine the detail sensitivity of iCT data sets. Round Robin Tests will be conducted, and the results will be made available to relevant standard committees to demonstrate the accuracy of the developed measurement systems. The project will prepare a draft standard or EN ISO 15708-5 ‘Radiation methods for computed tomography — Performance Evaluation and Long-Term Stability’. Moreover, the project will publish free reference software with evaluation algorithms that comply with the standard draft, as well as a free data bank with standard reference images that can be used to validate software for conformity. Overall, these advancements will support Industry 4.0 in Europe and guarantee the competitiveness of modern iCT applications.